Product Categories

Contact us

TEL: +86 13669822659

Email: info@qijunhardware.com

Whatsapp/wechat: +86 13669822659

Skype: alina6832

CNC lathe turning parts

CNC Custom Metal Parts and Industrial Components

|

Product Name

|

Custom Precision Turning Milling Parts

|

|||

|

Custom Services

|

CNC Machining Service; CNC Milling Service;CNC Turning Service

|

|||

|

Available Materials

|

CNC Machining Aluminum Alloys, Copper Alloys, Bronze Alloys, Brass Alloys, Stainless Steel Alloys, Steel Alloys, Titanium

Alloys,Zinc Alloys, And Plastic CNC Machining Materials |

|||

|

CNC Machining Finishes

|

Bead Blast, Tumbled, Anodized (Type II Or Type III), Titanium Anodize, PTFE Impregnated Hard Anodize, Chem Film (Chromate

Conversion Coating), Passivation, Powder Coat,Electropolishing, Electroless Nickel Plating, Silver Plating, Gold Plating,Zinc Plating |

|||

|

CNC machining & turning capabilities

|

5 Axis Machining up to 12″

|

|||

|

4 Axis Machining up to 20″

|

||||

|

3 Axis Machining up to 33″

|

||||

|

Dual Spindle Lathes with 32″ Swing, 18″ Max Diameter, and 8″ Chuck

|

||||

|

Drawing Accepted

|

IGS、STP、X_T、DXF、DWG、Pro/E、PDF

|

|||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|||

|

MOQ

|

Low MOQ Start 1 Pcs ( No need mold cost ) , Many Customer found us make prototype product to save Investment Funds for Pre-R&D and

Market Testing |

|||

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity

|

|||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official

Bulk Order. |

|||

Processing Material Selection:

Plastics:

CNC machining can work with many types of plastics, including ABS, acrylic, nylon, PEEK, polycarbonate, and PVC. These

materials are lightweight,cost-effective, and have good chemical and impact resistance.

materials are lightweight,cost-effective, and have good chemical and impact resistance.

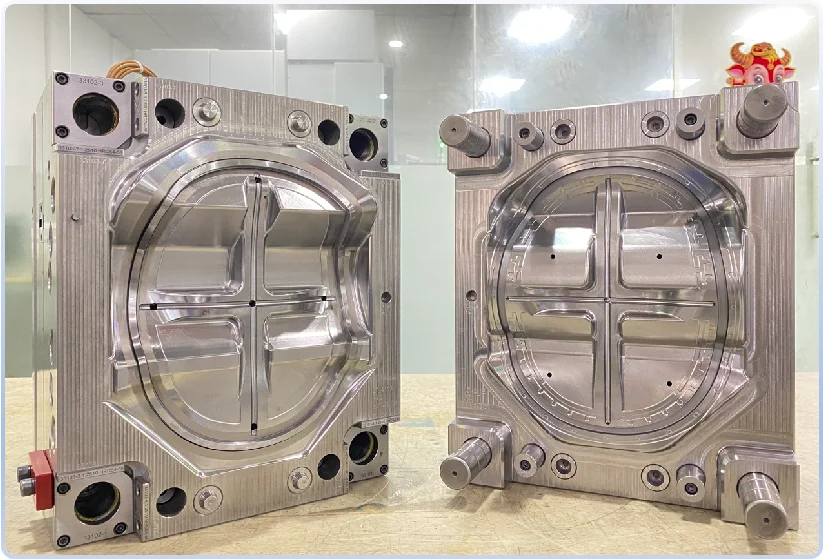

Some Custom Plastic Parts & Moulds for Your Reference.

Ceramics:

CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic mate.

CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic mate.

Metals:

Metals like aluminum, brass, copper, stainless steel, and titanium are popular choices for CNC machining. They are durable, have high tensile strength, and can be easily machined to produce complex parts.

OEM/ODM Plastic injection Mould product Material: abs,pc,pom,pa,hdpc,peek,pc/abs,pvc, etc.

Tolerance: +/-0.01~0.005mm

Surface treatment: electroplating, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot

peening,etc.

Tolerance: +/-0.01~0.005mm

Surface treatment: electroplating, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot

peening,etc.

Plastic / Injection Molding Material: BRASS HPb59, H59,H62,SUS304,SS316, 6061-T6,6063,6082,7075,TA2/GR2, TC4 etc.

Tolerance: +/-0.01~0.005mm.

Surface treatment: spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer

printing, engraving,etc.

Tolerance: +/-0.01~0.005mm.

Surface treatment: spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer

printing, engraving,etc.

Custom Plastic Part Injection Molding Product for Household Product Plastic injection Mould product

Material: abs,pc,pom,pa,hdpc,peek,pc/abs,pvc, etc.

Tolerance: +/-0.01~0.005mm

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hardanodizing, heat treatment, etc.

Material: abs,pc,pom,pa,hdpc,peek,pc/abs,pvc, etc.

Tolerance: +/-0.01~0.005mm

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hardanodizing, heat treatment, etc.

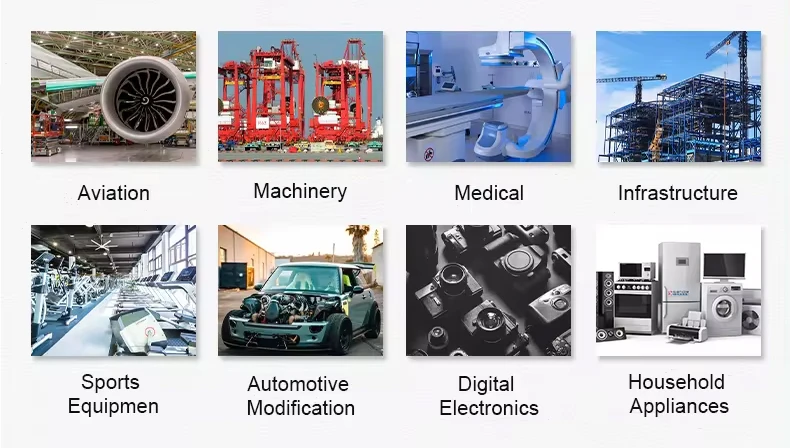

APPLICATION AREA

Aerospace:

The aerospace industry requires precision parts with high accuracy and tight tolerances. CNC machining services are

used to produce parts such as turbine blades, engine components, and structural parts.

used to produce parts such as turbine blades, engine components, and structural parts.

Automotive:

The automotive industry relies on CNC machining services to produce high-precision parts for engines, transmissions, and other critical components.

Motorcycles:

Engine components,Suspension components,Wheels,Brakes,Frame and chassis components,Exhaust systems.

Engine components,Suspension components,Wheels,Brakes,Frame and chassis components,Exhaust systems.

Bicycle:

Bike frames,Forks,Handlebars,Pedals,Brake components,Cranksets,Hubs. Medical: The medical industry requires precision parts for various medical devices and equipment. CNC machining services are used to produce components for surgical instruments, implants, and prosthetics.

Electronics:

The electronics industry requires precise components for various electronic devices. CNC machining

services are used to produce components for circuit boards, connectors, and other electronic devices.

services are used to produce components for circuit boards, connectors, and other electronic devices.

Oil and gas:

The oil and gas industry relies on CNC machining services to produce components for drilling equipment, pumps, valves, and other critical components.

Robotics:

The robotics industry requires precision components for robots and automation systems. CNC machining

services are used to produce components such as gears, actuators, and other robotic parts. Industrial machinery: CNC machining is used to produce parts for a wide range of industrial machinery, including pumps, valves, and bearings.

services are used to produce components such as gears, actuators, and other robotic parts. Industrial machinery: CNC machining is used to produce parts for a wide range of industrial machinery, including pumps, valves, and bearings.

Construction:

The construction industry uses CNC machined parts for components such as structural steel, cladding systems, and architectural features. Agriculture: The agriculture industry uses CNC machined parts for components such as irrigation systems, seed drills, and harvesting equipment. Marine: The marine industry uses CNC machined parts for components such as propellers, rudders, and hull structures.

Packaging:

The packaging industry uses CNC machined parts for components such as molds, dies, and cutting tools. Food processing: The food processing industry uses CNC machined parts for components such as cutting tools, conveyor systems, and mixing equipment. Furniture: The furniture industry uses CNC machined parts for components such as chair frames, table legs, and decorative features.

Packing & Delivery